4 tips for shippers to navigate produce season in 2023

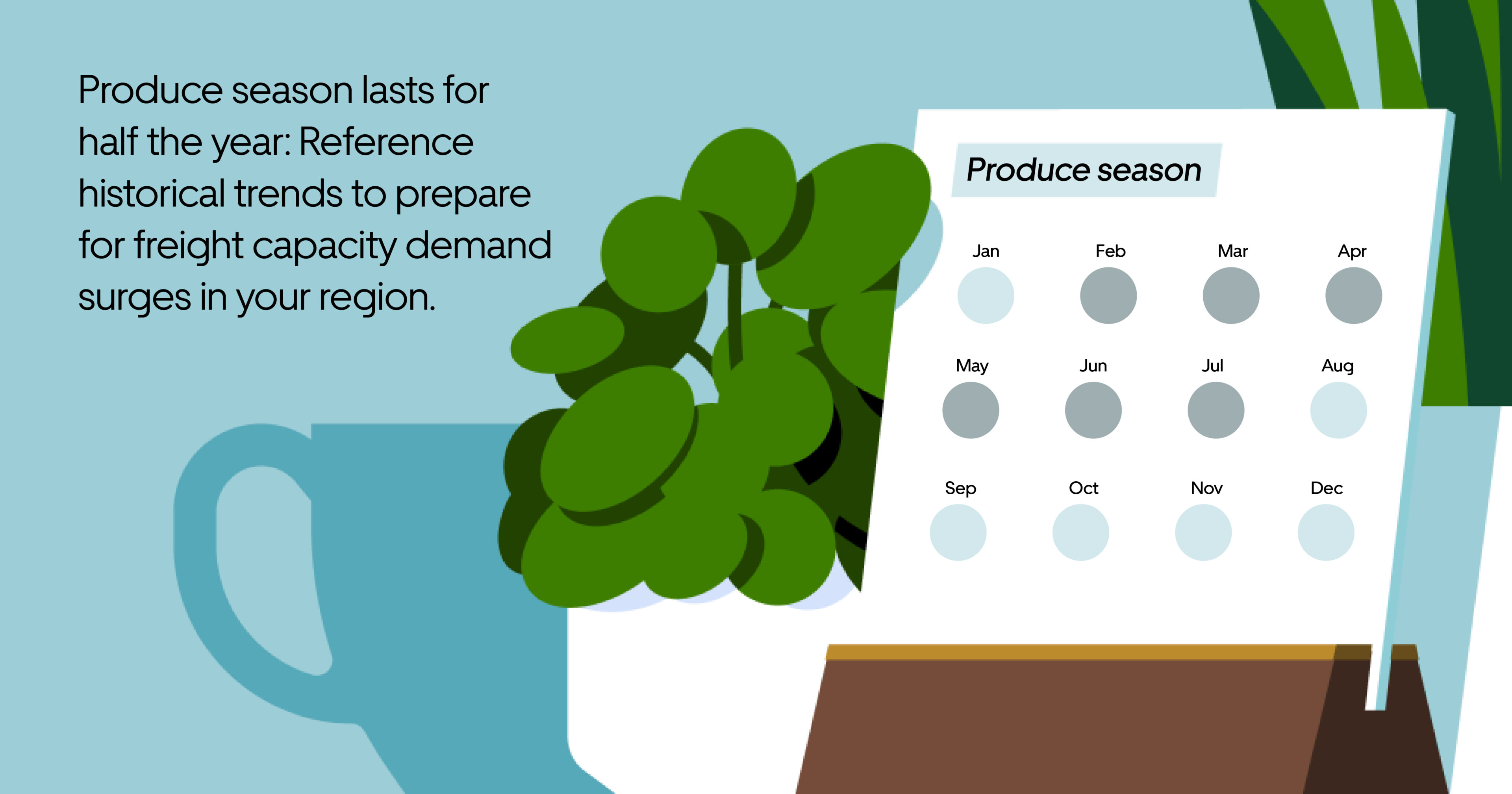

No matter what you’re shipping, it’s time to plan for produce season. Starting in February and continuing through July, different fruits and vegetables become ready for harvest—and cause a rush in demand for freight capacity. As a result, produce season is marked by unpredictable fluctuations in rates and capacity for all CPG shippers.

Experienced shippers know that when life gives you lemons—or oranges, or strawberries or soybeans—planning ahead is key to profitability.

Map out the impact to your shipping lanes

While nature dictates harvest timing, shippers should start by referencing historic trends to prepare. Demand typically increases in the southern US in early spring and moves north as the weather warms. Southbound shipment rates decrease during this time, as trucks carry more loads of produce along northbound routes.

Rates for shipments out of agricultural areas can jump when crops are at their peak. Take a look at harvest schedules to anticipate the timing and length of these peaks. For instance, produce season in the Florida region begins in mid-April and lasts through July. Shippers near major agricultural hotspots such as Florida or Texas should also anticipate a decrease in available capacity as trucks accommodate the agricultural shipments in these areas.

Plan shipments around these forecasted surges to ensure produce is shipped safely, in the proper packaging and right temperatures.

Prepare for rate and capacity fluctuations

Competition for capacity will increase dramatically during produce season, especially for climate-controlled shipping and reefers. While planning will help mitigate some of the impact, unpredictability around when certain produce will affect the market is inevitable. Weather can contribute to delays before and after harvest time. For example, a blizzard could delay certain harvests while a hurricane or other extreme weather could impact transportation and result in produce not being delivered on time.

Manage these fluctuations by creating an accurate volume forecast and planning for unforeseen scenarios ahead of time. Scenario planning will help you proactively lock in rates to ensure fair pricing and efficient procurement, as well as develop a system to address weather-related events.

Take advantage of real-time technology

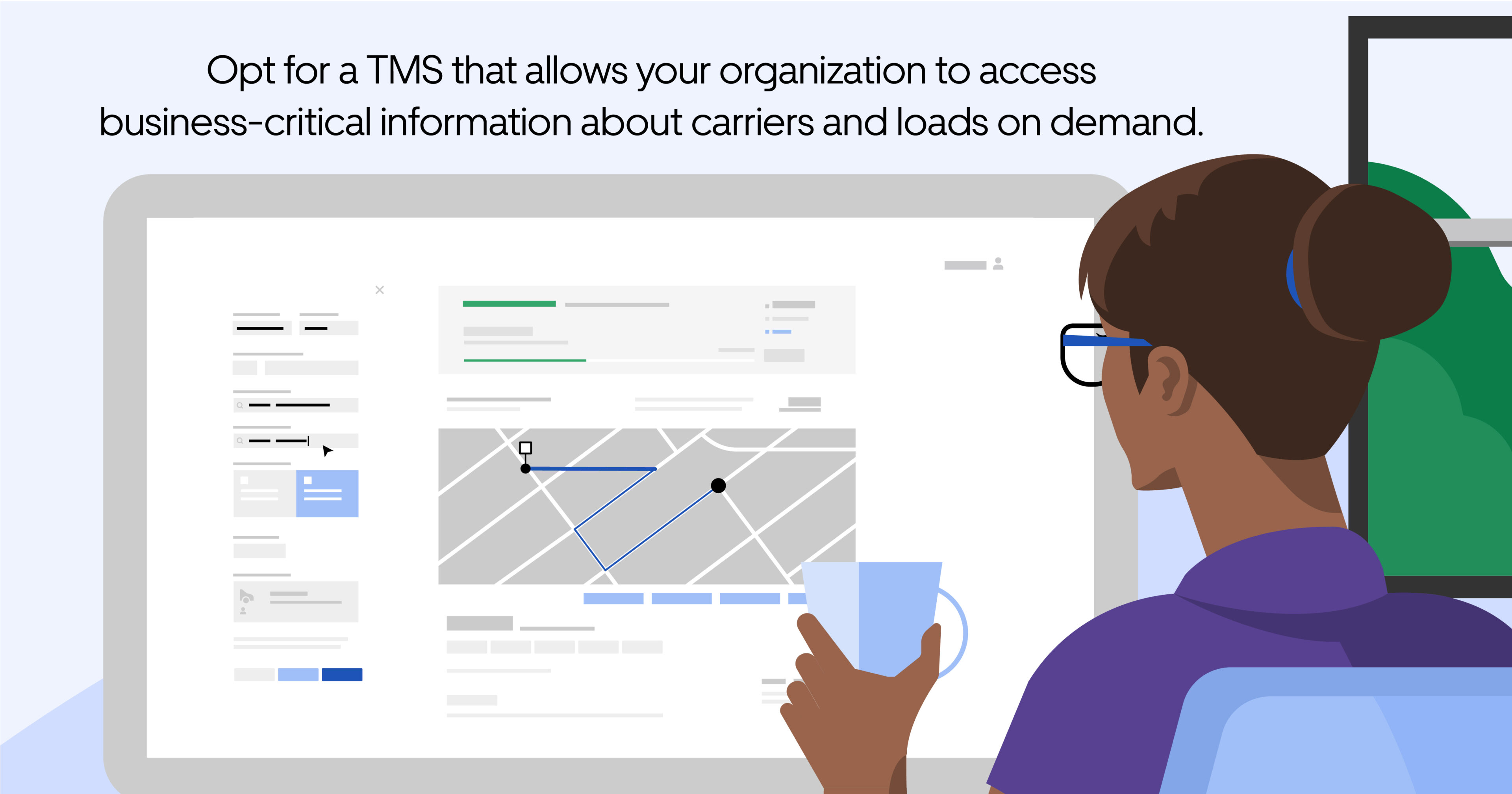

To handle dynamic capacity and costs, opt for a transportation management partner with a TMS that offers real-time data visibility, flexible procurement solutions and a network of digitally-enabled carriers—allowing your organization to access business-critical information about carriers and loads whenever you need it.

The insight technology can provide is even more valuable when you’re shipping produce and have unique considerations such as cold-chain continuity and tight timing. Even an hour in the sun can mean the difference between safely delivered goods and an unsellable load. Real-time tracking allows shippers to stay up to date on these time-sensitive, climate-controlled goods.

Choose robust and compliant support

![An experienced logistics partner will help shippers strategically source capacity and navigate surges and falls in demand. [picture of groceries]](https://www.uberfreight.com/wp-content/uploads/2023/04/UF-Produce-Season-Blog-Post-Infograpics-04-scaled.jpg)

The right transportation management partner will have experience navigating these surges and falls in demand, and help you strategically plan shipments. If you are shipping produce, work with carriers who are compliant with the Food Safety Modernization Act (FSMA). Ensuring compliance is important in its own right, and also helps shippers and carriers confirm their goods are handled correctly and remain intact.

While no one can anticipate every hurdle, working with a fully managed transportation service provider that has the necessary expertise and solutions will help you establish a comprehensive strategy to tackle future disruption.

Add experience to your team with Uber Freight. Connect with a representative today to strategically navigate produce season.